Case Study: Poultry Manufacturer

Background

High-volume poultry production requires precision, compliance and efficiency. This UK-based manufacturer runs several sites nationwide, supplying poultry products to retailers and foodservice customers, with quality and safety at the core of operations.

Hellenic Systems has been working in partnership with this manufacturer for over 30 years, delivering technology solutions that evolve alongside their operations.

The Challenge

The poultry division needed a robust manufacturing execution solution to manage order processing, batch control and full end-to-end traceability. With complex production lines and a need for accurate, real-time data, reliance on manual or disconnected systems could lead to inefficiencies, compliance risks and slower throughput.

Ensuring that every stage – from intake through to dispatch – was fully integrated and compliant was a top priority.

The Solution

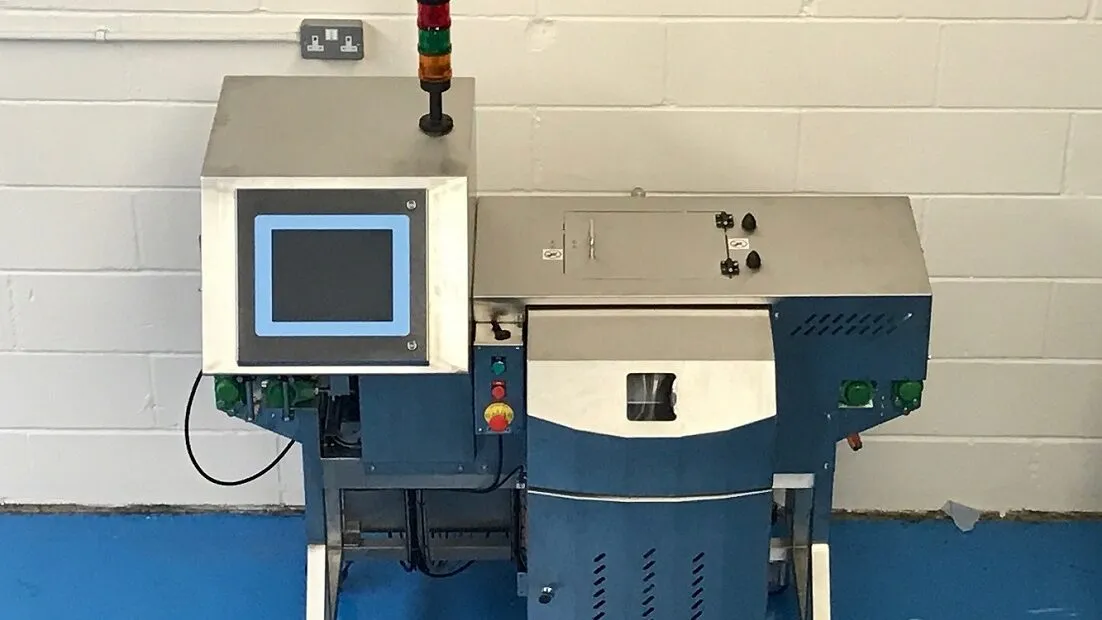

Hellenic Systems partnered with the manufacturer’s poultry sites to deliver a fully integrated FOPS8 (Factory Order Processing System), supported by our advanced hardware solutions.

The tailored system addressed:

- End-to-end traceability: Full visibility from live bird intake to final product dispatch.

- Order processing efficiency: Automated sales and purchase order handling with detailed tracking.

- Batch control: Accurate monitoring of production batches to ensure consistent quality and regulatory compliance.

- Labelling and weighing integration: Configurable solutions for accurate, compliant labelling on high-speed lines.

- Real-time reporting: Immediate access to production data for proactive decision-making.

The implementation was carefully aligned with existing workflows, ensuring a smooth transition without disrupting production schedules.

Factory Order Processing System (FOPS8)

Total factory systems management for optimised product processing

The Results

Following implementation, the poultry sites have experienced significant operational improvements. In our recent customer satisfaction survey, the manufacturer praised our consistent support and long-standing reliability across their poultry sites.

Key benefits include:

- Operational efficiency: Reduced manual intervention and improved production flow.

- Compliance confidence: Stronger assurance in meeting strict regulatory and customer standards.

- Rapid support response: UK-based team always on hand to resolve issues quickly.

- Future-proofed technology: Continuous software enhancements to keep pace with industry demands.

- Proven partnership: Over 30 years of collaboration, trust and shared success.

Hellenic’s software and hardware support teams have been excellent over the years I have worked alongside them. The response, knowledge and professionalism has been outstanding with great attention to detail on projects – they understand our site’s and how they work which has proven to help with minor oversights that would otherwise be overlooked. It’s a pleasure to be working with Hellenic Systems

Manufacturing Systems Developer

Why it Works

Hellenic’s in-house development and UK-based support ensure that the solution keeps evolving in step with operational needs. For the poultry division, this means technology that is not only reliable today but ready for the challenges of tomorrow – backed by a proven partnership spanning more than three decades.

Ready to optimise your production process?

If your business needs reliable traceability, efficient order processing and dedicated support for high-volume food production, Hellenic Systems can help. Our solutions are built to fit your operation, delivering measurable results without disrupting the flow of production.