FOPS8: Factory Order Processing System v.8

Total factory systems management for optimised product processing.

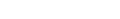

The FOPS8 provides comprehensive management of your factory operations, from order scheduling to real-time yield control and streamlined stock management.

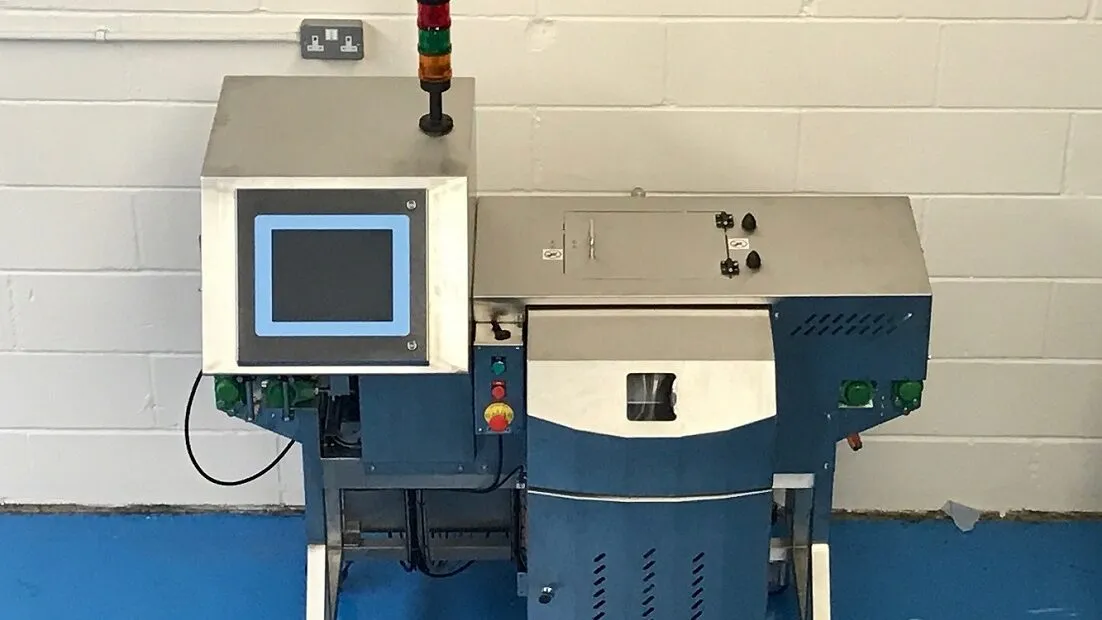

Designed for the food industry and beyond, it automates data capture and process routines, integrating seamlessly with your existing systems and hardware.

Product Overview

FOPS8 is the latest evolution of Hellenic Systems’ Factory Order Processing System, designed to provide total control over your food processing operations. Its modular design and SQL database architecture ensure flexibility, whether you’re running a single plant or a multi-site operation.

FOPS8 automates critical processes such as order scheduling, batch and yield control, stock management, and sales/despatching/invoicing, integrating seamlessly with third-party accounting and management systems to improve efficiency and reduce costs.

Top Features

- Multi-Site Management – Centralised control for operations across multiple locations.

- Sales Order Processing – EDI integration, sales analysis, and history tracking.

- Purchase Order Processing – Automated GRN, reject notes, and supplier performance analysis.

- Real-time Yield Control – Batch intake/output automation with costing analysis.

- Recipe Formulation – Integration with FORMIX for managing recipes and ingredients.

- Automated Systems – Integration with robotic warehouse management and auto-OCM systems.

- Comprehensive Reporting – Embedded and web-based reporting for informed decision-making.

- Retail Packing Integration – Seamless connectivity with WPL systems.

Integrations

- Accounting Systems – Standard interfaces with many 3rd party systems; custom interface development available.

- EDI Systems – For electronic data interchange in sales order processing.

- WPL Systems – Integration with automated packing lines.

- Robotic Warehouse Management Systems – Integration for automated goods handling.

- Label Design Software – Integration with LDII Label Design Manager.

- ERP Systems – Integration module for interfacing with ERP systems for order and stock inventory.

Industries

- Food Processing – Core application area.

- Meat Processing – Includes kill line, boning hall, and retail packing applications.

- Warehouse Management – Integration with warehouse management systems for factories.

- Apparel Warehousing – Stock, Payments and Invoice Management.