2026 is shaping up to be a defining year for food manufacturing regulations. With new rules on product advertising, tighter expectations around traceability and growing pressure on sustainability and waste reporting, the landscape is shifting fast.

For many businesses, the challenge isn’t what’s changing, it’s how to stay compliant without slowing down production or adding layers of admin to already busy teams.

The good news? With the right systems in place, compliance can become an opportunity to strengthen efficiency, accuracy and operational control. Below, we break down some of the key changes coming in 2026.

New advertising restrictions on “less-healthy” foods

The UK Government has confirmed that long-planned restrictions on advertising “less-healthy” food and drink products will come into force on 5th January 2026.

Key rules include:

- A 9pm TV watershed for adverts featuring identifiable “less-healthy” products.

- Restrictions on paid-for online advertising, with very limited exceptions.

- A broader definition of “less healthy” than traditional HFSS classifications.

Manufacturers must accurately classify products, validate nutritional data and ensure marketing teams are working with the right product categorisations.

Extended Producer Responsibility (EPR) regulations – coming January 2026

From January 2026, the UK’s new Extended Producer Responsibility (EPR) rules will place greater responsibility on businesses for the full lifecycle of their packaging. This means food manufacturers will need to collect accurate data and may face higher fees for packaging that is difficult to recycle.

What’s changing:

- You must report detailed information on packaging materials, weights and recyclability.

- Fees will increase for packaging that’s harder to recycle and decrease for more sustainable formats.

- You’ll need reliable, consistent data to avoid non-compliance or unnecessary costs.

Increasing traceability requirements & labelling expectations

While not all traceability rules are tied to one 2026 deadline, the industry is moving towards stricter expectations across origin, batch data, audit trails and digital records. Retailers, auditors and regulators are all tightening standards.

Your 2026 challenges:

- Being able to trace ingredients from intake to dispatch in seconds.

- Ensuring every label, case and pack is applied correctly.

- Reducing reliance on manual data entry.

- Maintaining fully auditable digital records.

Growing pressure on sustainability, packaging & waste reporting

Expectations around sustainability data, from packaging recyclability to food waste metrics, are becoming part of everyday compliance. Retailers are already requesting clearer information, and 2026 is likely to bring more consistent oversight.

Key areas manufacturers should prepare for:

- Transparent records of food waste, rework and yield.

- Better control of packaging errors (which directly impact waste).

- Reliable production data for sustainability reporting.

- Reduced reliance on manual waste-tracking logs.

Why 2026 marks a turning point

2026 will be a decisive year for compliance, with retailers and auditors expecting accurate, accessible and digitally recorded production data. Businesses still relying on manual systems, disconnected spreadsheets or reactive processes will face higher risks of non-compliance, inefficiency and unnecessary waste.

In contrast, factories with automated traceability, recipe control, batch visibility and label verification will be far better positioned, not just to meet requirements, but to run more smoothly overall.

To prepare, focus on tightening key areas over the coming months:

- Ensure your nutritional data is accurate and recipes are properly controlled.

- Map your traceability processes and fix manual gaps.

- Strengthen label and date-code verification.

- Review how you track and record waste data.

- Align your systems with retailer and auditor expectations.

- Explore automation where it reduces errors or manual workload.

Stay ready for 2026 with Hellenic Systems

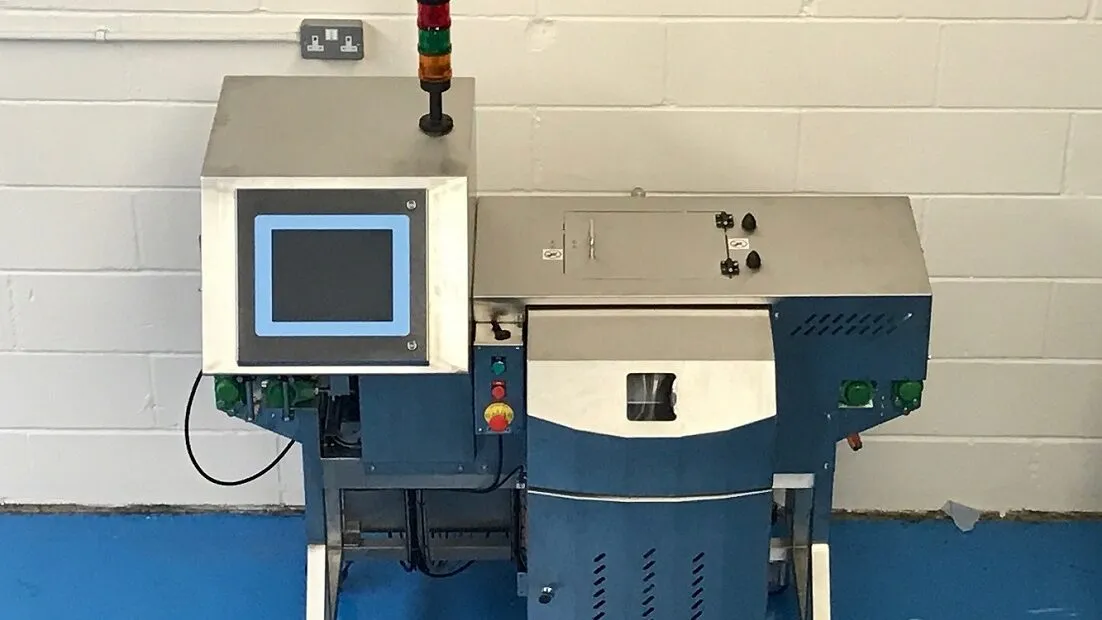

With over 35 years’ experience delivering software, hardware and integrated manufacturing solutions, Hellenic helps food producers stay compliant while improving efficiency, accuracy and confidence across the factory floor.

If you’d like support preparing your site for 2026’s requirements, chat to our team today.