At Hellenic, we’ve seen first-hand the challenges food manufacturers face: shrinking margins, intensive regulation and the ever-present pressure to do more with less. When you’re working with perishable raw materials, complex production flows and tight supply chains, any inefficiency can quickly turn into real cost and waste.

That’s where a Manufacturing Execution System (MES) makes the difference. Sitting between your ERP and the shop floor, a well-designed MES gives you the visibility and control you need to manage production in real time — from ingredients and recipes to line performance, quality and yield.

Here’s how it works, and how our MES solutions are helping food manufacturers stay efficient, compliant and competitive.

Why waste really matters in food production

Whether you’re producing chilled ready meals, snack bars, meat products or beverages, you operate in a world where time, temperature and precision matter. Too much stock and you risk expiry or quality loss. Too little and you risk missed orders or costly last-minute purchasing.

Every batch that’s scrapped, every ingredient that spoils, every line that stops unexpectedly — that’s margin lost and opportunity wasted. An MES helps you understand where and why those losses occur, so you can act quickly to prevent them.

What an MES solution brings to the table

Here are some of the practical ways an MES helps food manufacturers stay in control:

“I know exactly what’s happening on my production lines.”

An MES captures live data from machines, operators and sensors, giving you a real-time view of production. You can see line speeds, downtimes, temperatures, weights and quality checks — helping you spot issues before they escalate.

“I’m making only what I need, when I need it.”

With real-time scheduling and production tracking, an MES ensures you produce to demand, not guesswork. That means less overproduction and fewer batches sitting idle.

“If something goes wrong, I can trace it fast and minimise the impact.”

An MES delivers full traceability, linking every finished product back to its ingredients, machines and operators. When a deviation occurs — a faulty sensor, an out-of-spec ingredient or a temperature drop — you can identify the root cause quickly and avoid a full-line scrap.

“My operators and supervisors are working from the same, accurate data.”

An MES replaces paper records and spreadsheets with digital workflows and dashboards. That means everyone — from the shop floor to management — can see accurate, live information and make confident decisions.

“We’re continuously improving efficiency and reducing waste.”

Performance data helps you spot bottlenecks, understand reject patterns and monitor OEE (Overall Equipment Effectiveness). You can measure improvement and adjust processes to get better with every batch.

How Hellenic fits into the picture

At Hellenic, we don’t take a one-size-fits-all approach. Our MES platform is modular, scalable, and designed around your specific production environment — whether that’s ready meals, meat processing, dairy, or beverage production.

Here’s how our components work together to deliver control and clarity:

- Recipe Management System: Digitally manage and update recipes in real time, recording every weigh-in from sub-assemblies to final batches. Supports traceability and reporting.

- Factory Order Processing System (FOPS8): Comprehensive management of your factory operations, from order scheduling to real-time yield control and streamlined stock management.

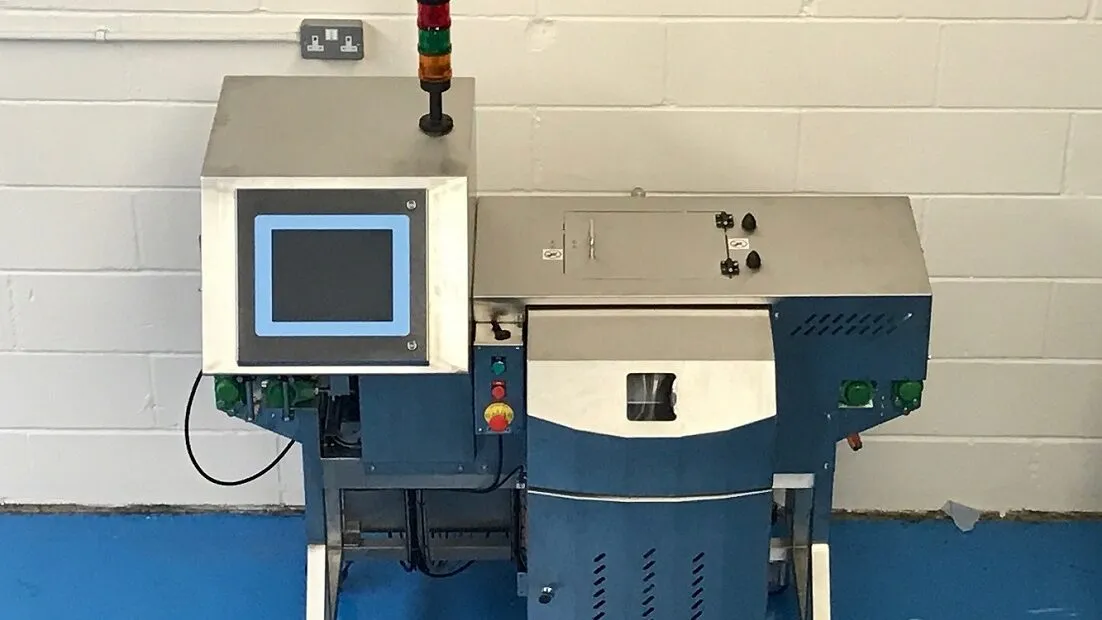

- Hardware & Data Capture: Reliable data is the foundation of MES. Our hardware (shop floor terminals, scanners, sensors) ensures every reading and transaction is captured accurately and instantly.

Together, these systems give you end-to-end visibility — from ingredient intake to finished goods — enabling you to reduce waste, improve yield and maintain compliance with ease.

Why this matters more than ever

In today’s food and drink manufacturing world, the pressure for traceability, efficiency and sustainability has never been higher. Every minute of downtime, every wasted batch, every manual error eats into profitability.

By implementing a smart, connected MES, you can build a more resilient, data-driven operation — one that minimises waste, maximises yield, and empowers your team with real-time insights instead of after-the-fact reports.

Ready to chat about your roadmap?

If you’re looking to gain more control over production, improve traceability, and drive down waste, we’d love to help. We’ve supported over 130 sites across the UK and Europe in achieving greater operational visibility through MES and integrated shop-floor systems.

Let’s explore your current challenges and design a roadmap that uses the right mix of software, hardware, and process to bring clarity and efficiency to your operations.

Get in touch today to discover how our solutions can simplify your processes.